FISCHER measuring and control technology

The German company FISCHER Mess- und Regeltechnik GmbH offers system solutions based on the measurement and control of physical quantities such as pressure, differential pressure, flow, level and temperature. Depending on the requirements, the systems are supplemented with other measurement technologies. In this way, the company provides a system architecture that meets the specific requirements for the realisation of trouble-free and cost-effective production processes. With FISCHER measurement and control technology, the user can optimise production processes and reduce production costs.

Pressure

Pressure gauges are among the most common pressure measurement devices worldwide. Fischer offers mechanical pressure gauges for accurate measuring of relative, absolute and differential pressure covering measuring ranges from 0…6 mbar to 0…1600 bar and compatible with almost every application.

Differential Pressure

Differential pressure gauges are designed to guarantee accurate reading of pressure differences between two points of your process. Typical applications are e.g. filter monitoring, hydrostatic tank level measurement in closed tanks and flow measurement.

Humidity

Three primary measurements of humidity are widely employed: absolute, relative, and specific. Absolute humidity is expressed as either mass of water vapor per volume of moist air (in grams per cubic meter) or as mass of water vapor per mass of dry air (usually in grams per kilogram).

Temperature

Temperature gauges are a good choice for local temperature reading close to the process. They are reliable, need no external power supply and allow constant process monitoring. Fischer temperature measurement solutions include bi-metal thermometers with various connections, stem diameters and lengths for local reading.

Signal Conditioning

Signal conditioning is a process of data acquisition, and an instrument called a signal conditioner is used to perform this process. This instrument converts one type of electrical or mechanical signal (input-signal) into another (output-signal). The purpose is to amplify and convert this signal into an easy to read and compatible form for data-acquisition or machine-control.

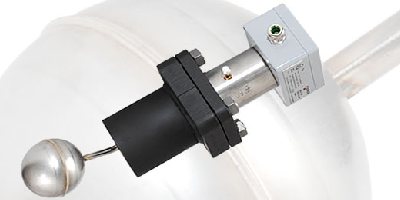

Level

Level measurement is the process of measuring the level of a liquid or solid material inside a tank, silo, container or other vessel. Measurement is calculated from the distance between the liquid or solid material surface and a predetermined reference point.