Conveyor optical contactless scales for bulk materials

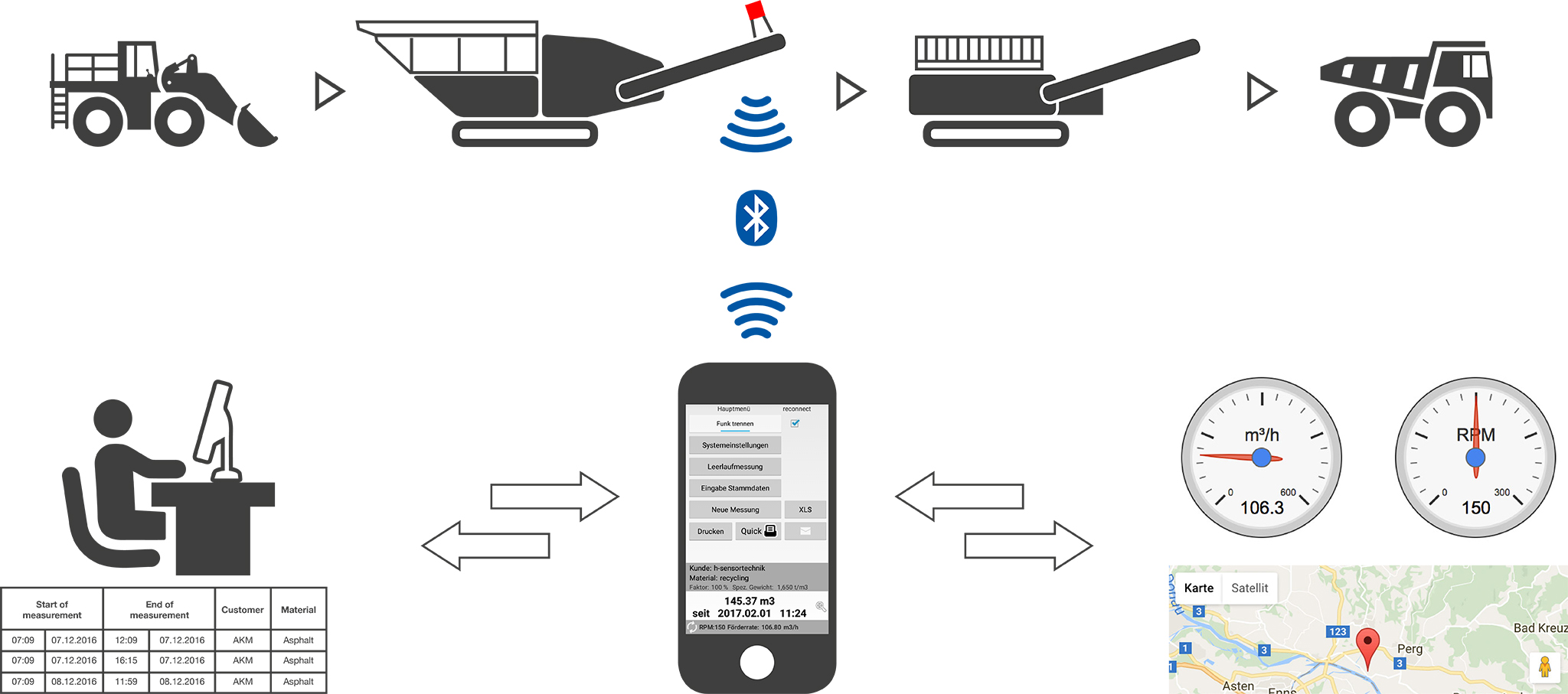

The non-contact electro-optical system measures the volume and weight of bulk materials on the conveyor belt and transmits the results wirelessly to a PDA smartphone, from where the information is forwarded to the operator's computer. The measuring system has no moving or wearing parts, is maintenance-free and insensitive to vibration, wind, dust or temperature fluctuations. The inclination of the conveyor belt is immaterial for the non-contact scales, which are connected wirelessly to a smartphone enclosed. The mounting location for the frame with the optical sensors is often the end shaft of the conveyor, although there can also be an intermediate shaft, and the enclosed speed sensor is mounted separately on the axis of this shaft. The system is only calibrated once, no recalibration is required and the system can be installed on a conveyor in 3-4 hours

The whole facility under continuous control

| By e-mail to any predefined recipient. The optical belt scale can be monitored and operated from your office. Thus, perpetual access and control is being offered, from the nodal point of the facility. | The included smartphone communicates via Bluetooth with the optical belt scale. Operation by personnel is not required. Only the device has to be within broadcasting range. | Live data can be retrieved at any time from any location. The team can also access the smartphone (after authority) via the network and carry out remote maintenance. On-site maintenance and the associated costs can thus be avoided. |